- August 10, 2020

- CPS News, Featured CPS News

- 4 Minute Read

For decades, friction-reducing coatings have been used to facilitate the insertion and placement of devices within the body. These coatings are often used on devices designed for use in the arterial and venous systems. Common products that use coatings to reduce friction include stents, catheters, bioabsorbable scaffolds, guidewires and other products that are in contact with the bloodstream. This is because blood becomes notoriously tacky the longer a device is in the artery or the vein, and can result in a device performing suboptimally.

Today, there are a variety of surface modification options available to device engineers, from hydrophobic to hydrophilic coatings. This allows them to select the solution that best matches their specific design and performance requirements.

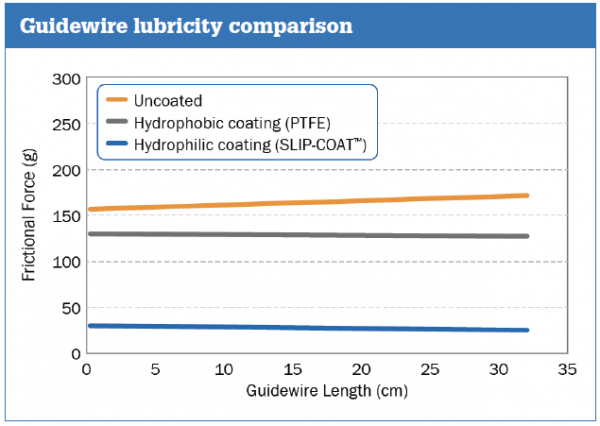

Slippery when wet

One of the original coatings used in the medical field is polytetrafluorethylene (PTFE). Widely used to coat guidewires, PTFE has the unique property of providing a low-friction surface in the dry state. Unlike hydrophilic polymers, PTFE does not need to be wet to provide lubricity. By contrast, polymers in hydrophilic coatings such as polyvinylpyrrolidone, which is contained in Argon Medical’s SLIP-COAT, absorb aqueous liquids to make the surface slippery when wet. This feature makes hydrophilic coatings more lubricious than PTFE coatings. Below is a graph comparing the force required to pull stainless steel guidewires between two silicone pads with 500g of applied force. Although the PTFE coated wire has lower frictional forces compared to the uncoated wire, the wire coated with SLIP-COAT is significantly more lubricious than both the uncoated and a PTFE coated wire.

Lubricious coatings are commonly applied to the outside surface of devices by dip, spray or wipe, followed by either curing with ultraviolet (UV) light or heat drying.

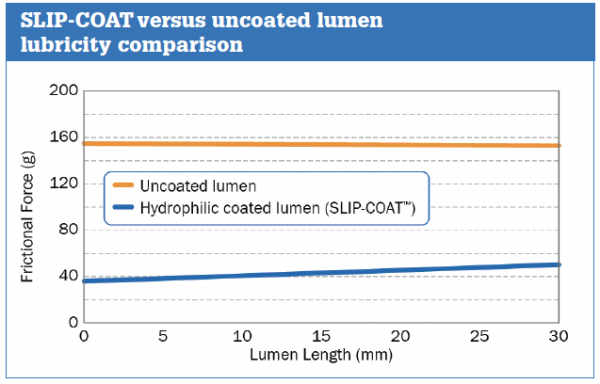

However, applying a coating to the inner lumen of a catheter is not as straight forward and presents a unique set of challenges. The first challenge is to introduce the coating solution into the lumen. This can be accomplished by injecting the solution with a syringe and then draining or flushing out any excess. The coating solution should have low viscosity so it can easily flow through the inner lumen without leaving too thick of a layer behind. The next challenge is to cure or bond the coating to the surface. A preferred method when coating lumens is to use a heat-curable coating to avoid the line-of-sight issues associated with UV-curable coatings. With a heat-curable coating, it is important to formulate with low-boiling solvents to facilitate their removal during the oven drying process. Blowing warm air down the lumen can accelerate this process.

Above is a graph showing the friction reduction when pulling an uncoated polyurethane tube out of the inside of a larger polyurethane tube. The lumen that was coated with SLIP-COAT dramatically reduces the frictional forces when passing one surface over another.

Friction reducing coatings have been, and will continue to be, an essential component of a variety of medical devices. The ability for a coating to be customised to meet all of the design and performance characteristics of a device is critical to the success of the product. Argon Medical’s SLIP-COAT can be tailored to meet a manufacturer’s requirements for the level of lubricity and the length of time a device remains lubricious. This customisation, combined with its ability to be heat cured, makes it a favourite solution for many manufacturers of vascular devices.